Dr Margaret Quinn

DIGITAL REGIONS partners and stakeholders had the opportunity to virtually visit the Swiss Smart Factory in Biel (Canton of Bern, Switzerland), on November 26th 2020. Unfortunately, due to these exceptional times, a physical visit was not possible. Despite this, attendees from Bulgaria, Germany, Ireland, Portugal, Romania, and Slovenia could feel they were almost on-site via a live tour through the facility and benefited from insightful, inspiring presentations on how the region is supporting SME’s on Industry 4.0.

The aim of the visit was to learn about the good practices directed at increasing manufacturing SME’s engagement on Industry 4.0. Our host Dominic Gorecky noted the importance of collaboration, both in DIGITAL REGIONS and more widely, as typically SME’s have limited time, resources, understanding on how to face the complexity of I4.0 and digitalisation to be in a position to grasp benefits.

The inspiring story of the Switzerland Innovation Park Biel/Bienne (SIPBB), the host of Swiss Smart Factory, was told by Thomas Gfeller, SIPBB-Chairman. Started 8 years ago, SIPBB is itself a start-up. Two key strategic shifts for its creation were noted: the regional diversification from watch manufacturing into med-tech by leveraging skills in precision engineering and the need to become capable of smart production via I4.0 technologies.

Many conversations were had with local companies who were saying that they lacked the critical size and technical strength to make the kind of radical changes needed for I4.0 adoption to be able to continue to compete globally. It emerged that what was needed was a platform for fast efficient access to resources that companies could not afford alone. For Thomas, this sharing of innovation resources was and is the key. The resources are both the brains of the people involved in SSF and SIBPP and the machines, the technical platform of 3D printers, robots, clean rooms etc. The overall vision is to offer an attractor for talent and ideas which serve industry of the region, and further afield, to improve innovation fitness – a training gym for company innovation!

The approach to innovation in the Swiss Smart Factory was explained by Dominic Gorecky along with their Good Practices and I4.0 Training Programmes. Though almost 10 years old, he noted that I4.0 is still not widely or fully implemented and that the COVID crisis constitutes an additional impetus behind it. Though DIGITAL REGIONS focus is on manufacturing, digitalisation encompasses many areas such a smart home, smart healthcare, smart mobility. The increasing business value with I4.0 is from connectivity, visibility, transparency, readiness via prognostic capability on to adaptability via autonomous optimisation.

The role of I4.0 in a new economic structure of increasingly customer-oriented value creation based on new logistics and production concepts was highlighted with examples such as MyMuesli. I4.0 adoption can be seen as a transformation process which is multi-faceted and inter-disciplinary, potentially bringing in horizontal integration across production units, digital twins of production, vertical integration across the whole production cycle with a range of technology such as data analytics, AR/VR, cloud computing...

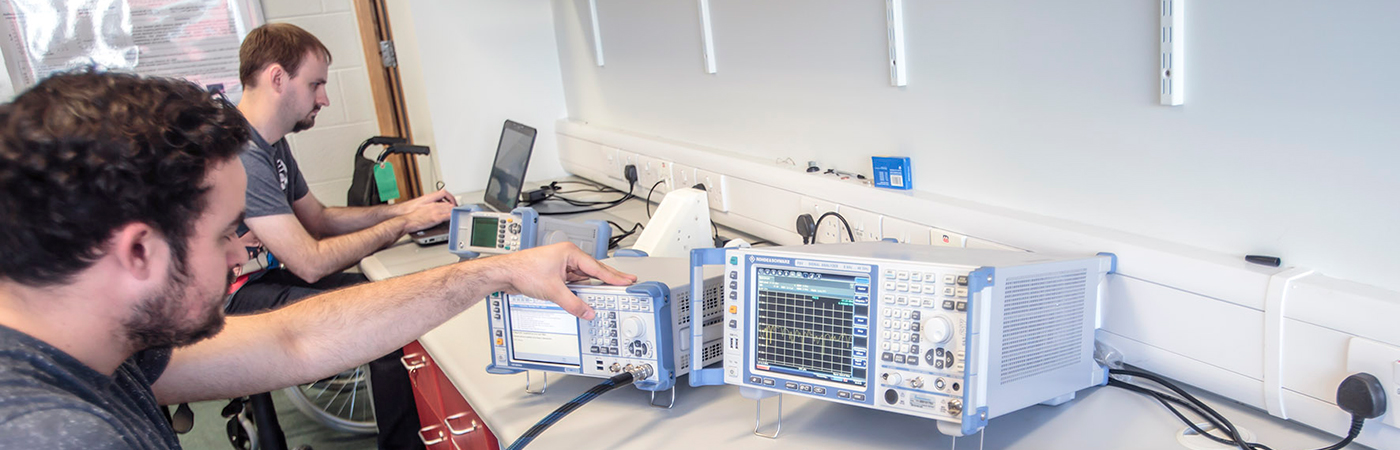

The undoubted complexity makes collaboration so important. The SSF good practice 'An open platform for technology adoption' is firmly based on collaboration as it coordinates the collaboration between technology / service providers & technology end-users. It starts with promotion and advocacy with “Inspire and Demonstrate” stage. Then is “test and develop” by prototyping & on to “training and support”. Prototyping examples were shown with computer vision & AI for a workflow recognition system. The playground “hands-on” aspect of training was shown in an example of machine learning workshops where participants solve a practical example from industry.

An I4.0 training workshop for 2021 is planned based on a one day team workshop with a training line to show best practice examples of digitization in production: Manufacturing Execution Systems, dashboards, auto-Id-solutions, assistance systems and AR. SSF acts as a neutral facilitating entity & has a membership model with a large number of I4.0 technology providers on board as members.

Thanks to Michael Wendling, Project Manager of SPIBB, we had live tour revealing the second good practice of Digitization Parkour, “consisting of several, interactive demo stations, helps to explore & analyse new technologies in a tangible and practise-oriented way” & comes from the Light House Project I4.0. The hands-on here was the I4.0 production cycle of a number of drone variants & the use of I4.0 to make it happen, from digital configuration, a 3D printing farm of parts, an automated & collaborative robotic production station, smart connected storage in smart lockers & toolbox, smart logistics & quality inspection.