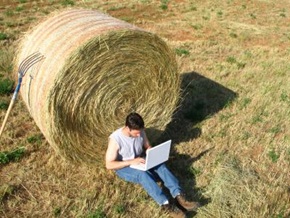

László Drávai and Zsuzsa Drávainé Schwáb goat and cows milk producers, meat, fruit and vegetable  processors welcomed us in Csór, Hungary, in the „Gacsó” view farm in order to tell us about their activities and plans.

processors welcomed us in Csór, Hungary, in the „Gacsó” view farm in order to tell us about their activities and plans.

"Our priority is not generating profit, but creating value” they emphasised in the very beginning.

Zsuzsa left her job at the post office, while László left his engineering career path behind in order to become full-time producers and be able to spend their days doing what they love. This happened in 2013. In the beginning, they were experimenting with traditional recipes from our "Grandmothers’ time” and used knowledge gained from the internet. As time passed by, they became better and better at making cheese.

At the time, the Gacsó view farm was the affectionate home to three jersey cows and 18 goats. Besides the daily nurturing and feeding of the animals, they milking their animals twice a day and processing the milk from that daily routine. This adds up to approximately 290 working hours per person in a month.

At the time, the Gacsó view farm was the affectionate home to three jersey cows and 18 goats. Besides the daily nurturing and feeding of the animals, they milking their animals twice a day and processing the milk from that daily routine. This adds up to approximately 290 working hours per person in a month.

They think that it is not worth it to become a farmer for the sake of earning money, this job can be done only if one is passionate about animals. This unique characteristic of the job is the root of their biggest problem as well, which is the  lack of labour force. It is namely extremely hard for them to find someone who is willing to help them in the long run. The shortage of labour force is a common problem among the rural SMEs in Hungary, but in the case of the livestock industry the situation is even harder – the animals need to be looked after every day, regardless of weekends or national holidays.

lack of labour force. It is namely extremely hard for them to find someone who is willing to help them in the long run. The shortage of labour force is a common problem among the rural SMEs in Hungary, but in the case of the livestock industry the situation is even harder – the animals need to be looked after every day, regardless of weekends or national holidays.

There is much demand for their products, customers sign up two weeks ahead for the milk. In addition, their cheese became  popular not only among locals but among International customers as well. There are Japanese, French, Swiss and Italian customers in their clientele. What makes them unique is that they produce their products on a small scale, by keeping the traditions of handcraft processes. This allows them to continuously monitor and react to quality deviations. We did not see big cheese tanks or other types of equipment. They claim that in mass-production one loses control over the quality of the product. Although this technology requires more time, the

popular not only among locals but among International customers as well. There are Japanese, French, Swiss and Italian customers in their clientele. What makes them unique is that they produce their products on a small scale, by keeping the traditions of handcraft processes. This allows them to continuously monitor and react to quality deviations. We did not see big cheese tanks or other types of equipment. They claim that in mass-production one loses control over the quality of the product. Although this technology requires more time, the  continuously increasing number of buyers is proof that their quality policy is working. Their example shows that it is worthwhile to build a small business as well, there is much demand for handcraft, qualitative and unique products on the market. Their dream for the future is to be able to offer a wider range of products to their customers, including eggs, vegetables, fruits, chicken and pork. However, the realization of this needs to be postponed due to the lack of labour force.

continuously increasing number of buyers is proof that their quality policy is working. Their example shows that it is worthwhile to build a small business as well, there is much demand for handcraft, qualitative and unique products on the market. Their dream for the future is to be able to offer a wider range of products to their customers, including eggs, vegetables, fruits, chicken and pork. However, the realization of this needs to be postponed due to the lack of labour force.