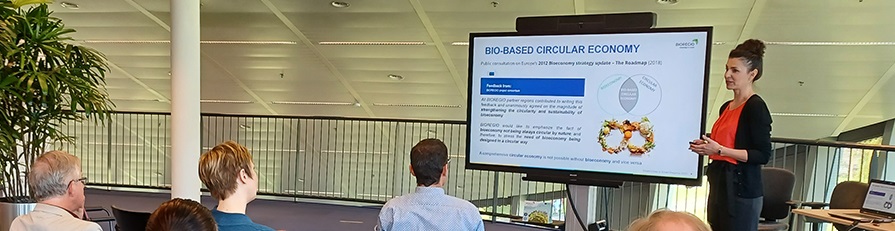

BIOREGIO was present at International Symposium of Chemical Engineering and Materials SICHEM 2018, organized on 6-7 September 2018 by Romanian Chemical Engineering Society and Politehnica University of Bucharest.

The Symposium held in the campus of University Politehnica of Bucharest, Library building, 313 Splaiul Independentei. INCDCP-ICECHIM presented at its stand R&D&I results and projects it is involved. It was a good opportunity to present BIOREGIO project, to distribute BIOREGIO brochures and to initiate discussions in the field of bio-based circular economy.

The event enjoyed a wide participation: representatives of the authorities, researchers, economic agents, around 120 participants in two days.