This session was dedicated to the presentation and discussion of the intermediate results of the feasibility study currently being carried out by VTT. The main issue was to review the feedback to the questionnaire that VTT and INNO PROVEMENT partner 8 RCK, had circulated among businesses. Eighteen questionnaires were answered, generating insights into all 92 questions. The participants were representatives from manufacturing SMEs and from research and education organisations, with attached specialised business support units. Total number of participants was 14 of which 12 participated on location and 2 online.

The meeting focused on digitalisation opportunities for manufacturing SMEs. The purpose was to capitalise on the answers received to the questionnaires, to gain further insights regarding the readiness of stakeholders towards adopting Industry 4.0 processes.

The workshop was opened by the Director of Regional Development Jouni Ponnikas from the Regional Council of Kainuu. He gave an outline of the progress of the INNO PROVEMENT project and outlined the purpose of the workshop. He was followed by Senior Scientist Leila Saari from VTT (Technical Research Center of Finland Ltd.) who presented I4.0 technologies, research programs and I4.0 implementation models for manufacturing industry. One particularly interesting point she raised was a national level forthcoming initiative ”Sustainable Industry X” (SIX), a national program to ensure the competitiveness of the Finnish manufacturing industry in the global market.

Jukka Kääriäinen, Senior Scientist from VTT presented the results of the survey made to Kainuu based manufacturing SMEs. The survey gave an opportunity for the businesses to assess their operative processes, where the costs are how digital tools are used now and what are the future plans. Some other interesting findings were the issues that hinder the uptake of digitalisation in the companies. As a conclusion Mr. Kääriäinen raised 3 topics:

1. Firstly, the biggest hindering factors for digitalisation uptake in companies are:

a. Lack of time to research the opportunities

b. Lack of work force with high digital skills

c. Lack of funding opportunities for investments in digitalisation

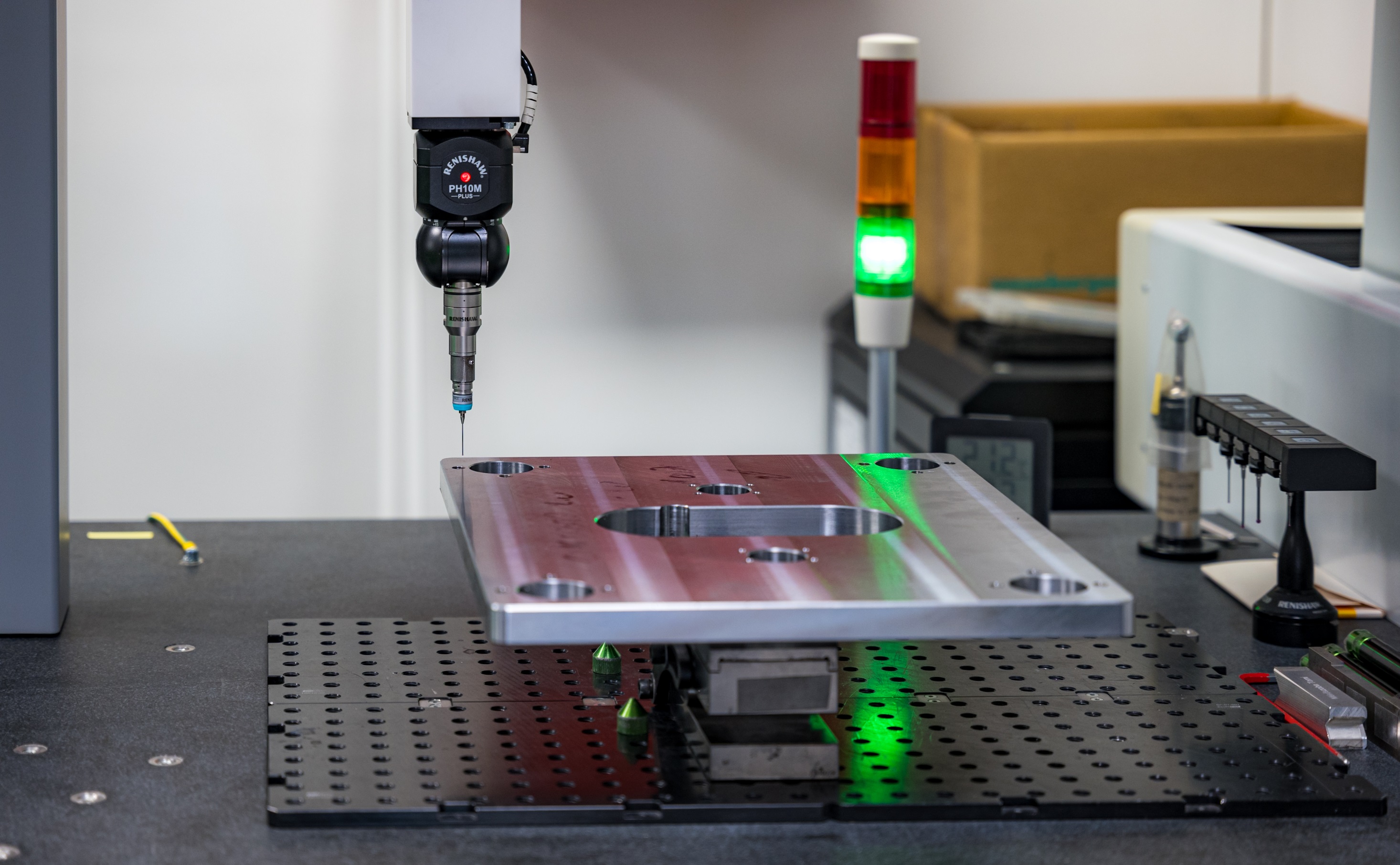

2. Secondly, the highest operative costs in the manufacturing companies lie in logistics, production and maintaining of production assets. The biggest opportunities to save costs by digitalisation are seen in production costs.

3. Thirdly, it was found out that the analysis and use of collected data in decision making, the automation of the production and using the digitalisation for resource efficiency were considered to be on low level in the companies.

The workshop part itself started with the group working on the solutions to the biggest hindering factors of uptake of digitalisation. Feedback ranged from ideas of trainings and pilot operations to raise the awareness and increase the skill level of employees. Also, the tailored support to single company needs was discussed as a solution to increase the uptake.

The biggest issue raised by the participating companies was the supply chain management and how the documentation, the quality control and product information could be shared in a complex supply chain. This raised a lot of discussion among the participants and possible development models to improve the situation. The fruitful event was concluded by Leila Saari from VTT.