Over the past years, the number of systems for measuring the maturity of businesses from an Industry 4.0 perspective has increased across Europe. These systems usually measure enterprises based on relevant and categorized factors. Measurement results are an important input to both the monitored enterprise and development policy as well. Within the framework of INNO PROVEMENT project, the partners shared several good practices demonstrating the Industry 4.0 maturity matrix. These practices were analysed to identify their possible application in the development policy and to note the similarities and differences in the measurement criteria.

The purpose of INNO PROVEMENT project under the Interreg Europe programme is to improve the innovation and technology related calls directed to SMEs in order to better align with Industry 4.0 challenges.

The project was launched in 2018 and is implemented by an international consortium of eight members, including the Hungarian Ministry of Finance as a lead partner. Consortium members are also the Ministry of Industry and Trade (Czech Republic), Thessaly region (Greece), Marche region (Italy), Łódź region (Poland), Kainuu region (Finland), COMPETE 2020 Managing Authority (Portugal) and also the ICT Association of Hungary as an advisory partner. During the five years of implementation, the project partners seek to develop their own policy toolbox by learning from each other’s experiences in the field of SME support policies related to Industry 4.0.

In Hungary the first meaningful initiative for the measurement of Industry 4.0 maturity was Industry 4.0 questionnaire project realized under the National Technology Platform. The National Technology Platform was established in May 2016 with the support of the Hungarian Ministry for National Economy and the participation of forty member organizations (enterprises, research institutes, universities, and professional organizations). The Platform was coordinated by the Institute of Computer Science and Automation of the Hungarian Academy of Sciences. The aim of the project was to define the companies’ digital and business maturity index in terms of digitization and to provide a proper picture on the direction of relevant macroeconomic developments. The main source of questions to assess the Industry 4.0 capabilities of companies was the Industry 4.0 Readiness Questionnaire developed by the German machinery and equipment manufacturers' association IMPULS Foundation and its accompanying study.

The EDIOP – 1.1.3 Industry 4.0 – priority project was launched almost simultaneously with the questionnaire project of the National Technology Platform, however the difference between the two is that in case of Industry 4.0 project the studies were conducted for the customized development of the participating companies. The results were validated by experts following a self-assessment of the companies according to a set of criteria. On the basis of the validated assessment, individual development plans for the companies were drawn up.

One of the foreign examples introduced as part of the INNO PROVEMENT project is the Portuguese SHIFT to 4.0 programme, which is an online self-assessment tool available for all types of enterprises (SMEs and large enterprises), it can be used to identify critical intervention areas and to prepare action, investment and financing plans.

During the pilot phase of the programme (until the end of 2019), 300 enterprises used the tool, 111 self-assessments were validated and 64 expert reports were delivered. As part of the programme, an Industry 4.0 professional and educational network has been set up for participating enterprises, together with a catalogue of best practices.

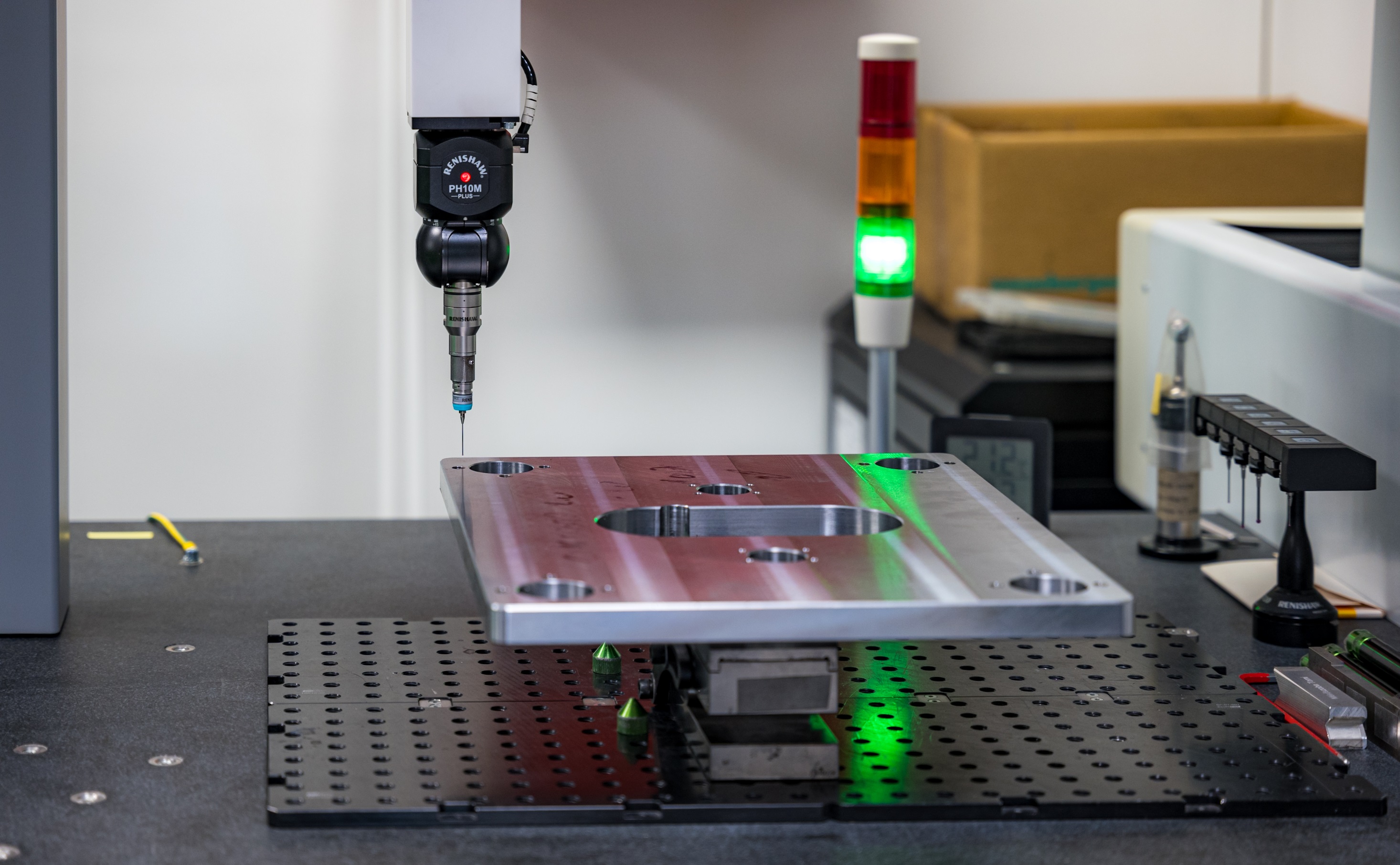

The AquaDigin model in Finland targets SMEs in the manufacturing sector, its approach is that measuring digital maturity is not sufficient, therefore this model also helps enterprises to transform digitally beyond measuring maturity. The model consists of four main modules: (1) maturity measurement, (2) positioning, (3) digital transformation roadmap, (4) implementation.

In the Czech Republic, the “Consultancy” call for proposals provides SMEs with a small non-reimbursable grant for the elaboration of their digital transformation plan. The Digital Transformation Plan should be submitted by SMEs as an annex to their technology development project plan under the “Technology” call for proposals. The evaluation of the digital transformation plan is part of the evaluation of the aid application, in this context, the enterprises’ current preparedness and the envisaged progress with the aid application are being examined.

On the basis of experience gained, it can be concluded that accessing the Industry 4.0 maturity matrixes can serve as a pre-screening tool for calls, or help to outline the development path tailored to the SMEs, and as a recruitment tool to identify those enterprises that are ready to adopt digital solutions, but have not yet committed to it.