Essential tools to improve the best olive processes and develop new olive-based products.

During the second Transnational Learning Journey a company in Navarre region shared its experience about the use of life cycle methodologies: Biosasun.

BIOSASUN SUBTITULOS from 601 Producciones Audiovisuales on Vimeo.

The company

Biosasun, S.A is a SME located in the Basque Country-Álava and Navarra. Founded in 2001 by the interest of various professionals in the production of organic products.

Allotarra Association of Ecological Agriculture and Livestock is made up of various farmers from Tierra Estella-Lizarraga (Navarra). Its main activities are the practice and promotion of agricultural, livestock, commercial and professional activities. After cultivating organic olive trees for more than 30 years,its objective is to make organic farming and its sustainable processes available to all, always respecting the environment and its resources.

The Strategy of Company is represented in this graphic:

Extra virgin olive oil is 100% pure organic olive juice, of superior category obtained directly from olives and only by mechanical procedures. Always using agricultural techniques and in oil extraction processes, environmentally friendly techniques in organic agriculture.

The process of producing the oil that was subcontracted in a mill near the area, at the time of the study, consisted of: discharge of the olive, washing and removal of leaves, crushing, smoothing at low temperature, horizontal centrifuge, vertical spinning, storage in tank, decanting and packaging

LCA and Results

From January 2008 to December 2010 Biosasun was working in the European Project RECYWASTEOLHIVA: Recycling and reusing of all waste produced during olive oil production in order to develop high added-value products, led by the Technological Centre L´Urederra, where the LCA tool developed and used allowed the calculation of the ECOLOGICAL, ECONOMIC AND SOCIAL impacts of the classic production of extra virgin olive oil. This tool is based in the use of an impact matrix to improve processes and make them more sustainable:

CF diagnosis and Results

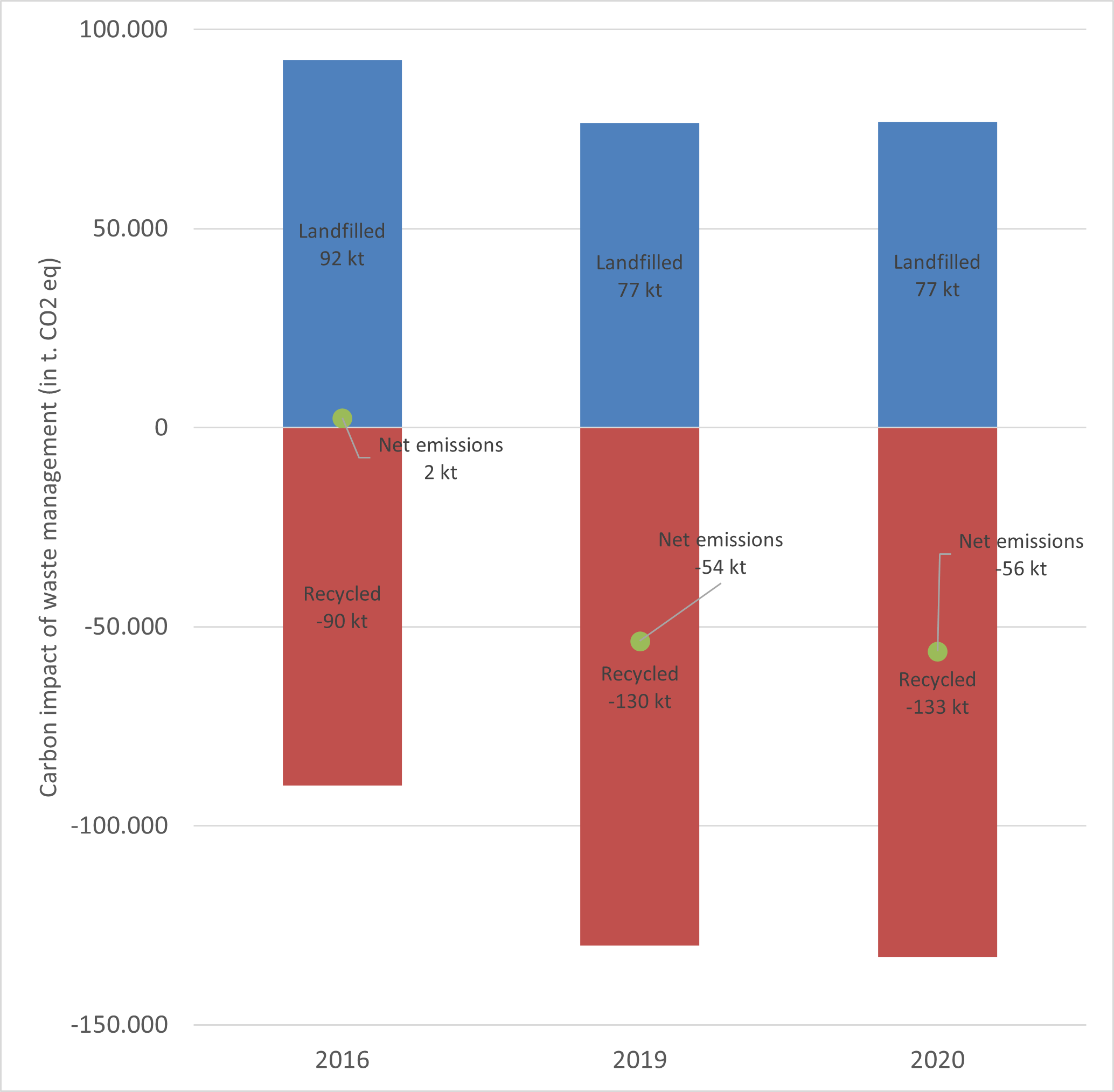

In 2012 Biosasun calculated the carbon footprint by determining the total amount of CO2 emissions and other greenhouse gases (GHGs) caused directly or indirectly. Based on the information collected, the value chain associated with oil production was determined by identifying the different inputs and outputs.

Read this case study to know more general limits, first action plan, action plan for the reduction of emissions in a technical-economic way, indicators monitoring, and more: