Désirée Neeb | Germany

On the 21st of October the time had finally come to welcome our international partners and stakeholders at Hof University of Applied Science. Due to Covid-19 restrictions, the event was held online but nevertheless it was a great pleasure for Hof University’s representatives to show the 25 participants, what we have to offer.

Morning Session: Hof University’s Start-Up ecosystem

> Digital Start-Up Center Einstein1

After some quality time for networking and introductions, we directly went to the first round of Good Practices, which were related to the Start-up ecosystem of Hof University. Hermann Hohenberger, the director of the Digital Start-up Center Einstein1, explained how the Start-up Center and its residence in a new building on the Hof University’s campus came to be. Participants could also learn what the goal and purpose of the Digital Start-Up Center Einstein1 is: A contact point for founders and start-ups from Upper Franconia and the Vogtland region.

The focus lies in Big Data and its potential applications for industry as well as in the energy and healthcare sectors. Furthermore Einstein1 provides many services for upcoming new Start-ups in the digital sector. In addition, Einstein1 proactively promotes networking opportunities with key players in business, science, education and politics through events and networking activities. Overall, Einstein1 ensures and enforces the fact, that the Upper Franconia region and the city of Hof is an attractive location for starting and successfully establishing a business.

Following a virtual tour through the whole building – including an autumnal view on the city of Hof from the rooftop – questions from the international audience were asked and answered. The topics ranged from the necessary number of staff members required to run the Start-up Center to possible cooperations on an international basis.

> Makerspace & Start-Up-Lab

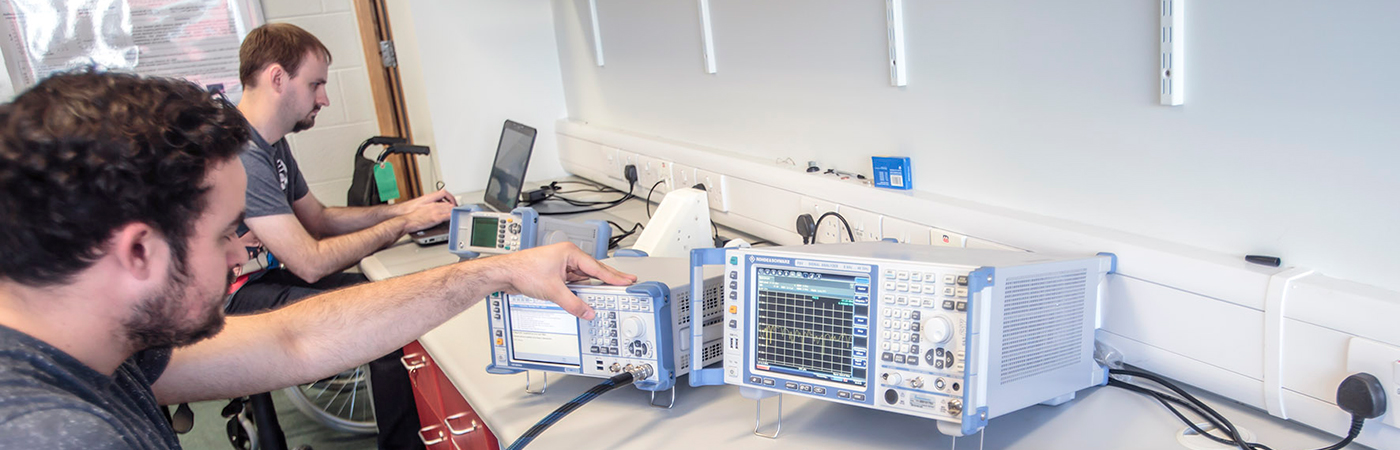

Next up was the project manager of the new Makerspace and Star-up-Lab of Hof University: Jörg Raithel. He went on to explain to the audience that as part of the Federal Ministry of Education and Research's "StartUpLab@FH" funding initiative, a contact point for tinkerers, hobbyists and creative people has been created on campus in the form of a MakerSpace prototype workshop and a ThinkBox creative space. Although it is for now primarily aimed at students at Hof University it is planned to widen the user range in the future. Technician René Göhring then gave the participants a short virtual tour through the Makerspace with all its tools and equipment including several 3D-Printers and a Lasercutter.

Afternoon Session: Hof University’s research and transfer projects

After a two hour lunch break the whole group then took a deep dive into the research and cooperation capacities of Hof University and specifically of its IT research institute iisys (Institute for Information Systems at Hof University). Prof. Dr. René Peinl, the new scientific director of iisys, told the audience about the two projects “Digital Production Workplace for SMEs (DFAP)” and “Highly Customizable manufacturing Exectution System (HiCuMES)”. Both of those projects were part of a bigger project called “Economy 4.0 in medium-sized companies (WiMit)”, which was funded by the European Union through the European Regional Development Fund. The idea behind these projects was – in general – to replace the still strongly paper-based production workstations with a digital solution.

What he and his team learned and what the participating audience could take away from that Good Practice was – for example – this: It is necessary to have an interested and involved industry partner, which in this case of the “Digital Production Workplace” was the manufacturing company Gealan Window-Systems GmbH in Tanna. Through the willingness of and the cooperation with Gealan GmbH this project became a door-opener for iisys to be seen by other companies as an effective and reliable partner. More collaborative projects with other companies then followed. Secondly, to be able to translate the results of the project into other companies it was necessary to understand, that production processes are highly company-specific. But basic steps are always the same (select order, quality assurance, confirmation etc.), which makes these types of projects a Good Practice to adapt in other companies.

The project partner Gealan GmbH kindly unlocked the company’s doors for the participants, which made it possible to also have a virtual tour through the production hall in order to see the implementation of the “Digital Production Workplace”. At the end of the session Prof. Dr. René Peinl could also announce a new project, called “Moonrise”, which is currently in the second application round and is inspired by the DIGITAL-REGIONS-Good-Practice “Development of Technological Capabilities for the Industrial Application of the Internet of Things” in Spain (Universidad de Salamanca).