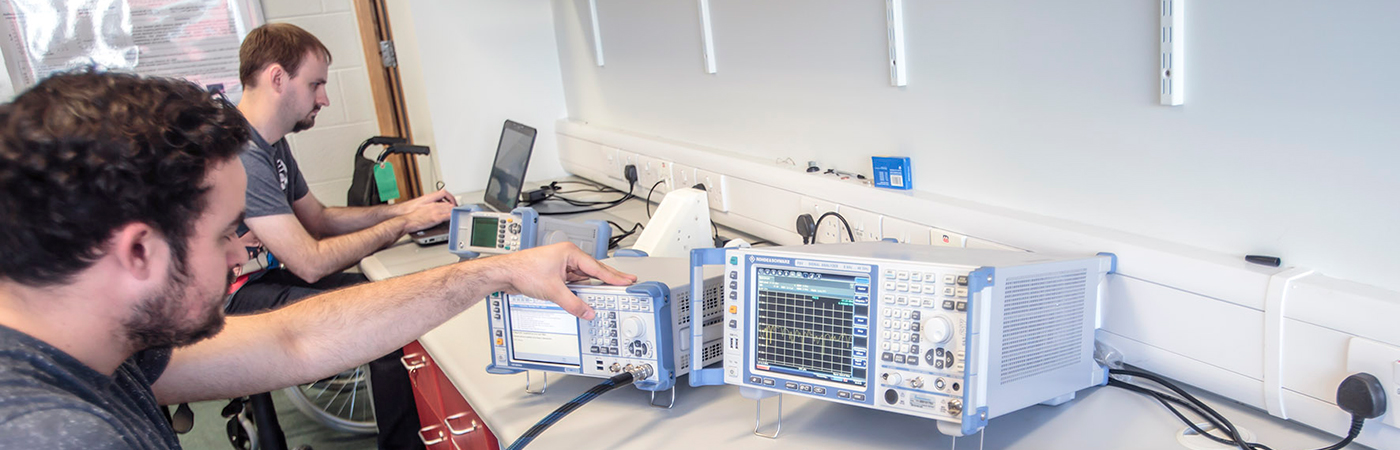

The WiSAR Technology Gateway, at Letterkenny Institute of Technology (Donegal, Ireland), has today unveiled a new €170,000 state of the art, 8-axis portable CMM (Coordinate Measuring Machine) arm, equipped with an ultra-high precision scanner and related software, following a successful submission to last year’s Enterprise Ireland's Capital Equipment Fund. The advanced technology will see the LYIT Department of Electronic and Mechanical Engineering research facility, significantly expand upon current test and prototyping capacity for industry in the North West region and beyond.

The revolutionary scanning device, typically adopted in the manufacturing sector, utilises both contact, via ruby tipped probes, and non-contact measuring technology, via the latest cutting-edge blue-laser 3D scanner, to convert physical objects into digital 3D models, with ultra-high accuracy down to 0.020mm. The equipment is designed for inspection, dimensional analysis, Computer Aided Design comparison, tool certifications and reverse engineering applications on parts and assemblies across a wide range of engineering businesses including automotive, marine, agritech and medtech.

Derek Thornton, of LYIT’s Department of Electronic and Mechanical Engineering, explains that the acquisition of this pioneering suite of equipment will enable the Institute to harness and accelerate the digital capabilities of a wide range of industry partners. “The speed of technological advancement coupled with the challenge to maintain competitiveness in a dynamic and demanding business environment, has driven a new industrial revolution, particularly in the manufacturing industry.”

“This new state-of-the-art, high-resolution scanner can quickly and accurately capture exact specifications of physical objects, from prototype design phase, right through to inspection and verification stage. These capabilities are fundamental for many engineering businesses to leverage unique design and rigorous quality control processes, particularly in the context of the growing consumer demand for personalisation, customisation and shorter lead times”, he adds.

LYIT’s Department of Mechanical and Electronic Engineering Technician, Johnny Morrow, highlighted that the cutting-edge equipment will complement the strong manufacturing cluster in the North West. “In this digital age, advanced manufacturing technologies such as 3D scanning, are key to industrial competitiveness and market growth. However, there are various barriers for businesses in accessing and adopting innovative processes which require significant financial and human capital commitments. High spec technologies, such as these scanning capabilities, are not readily accessible to most companies.”

According to him, “LYIT has seen a growing demand among industry partners for high resolution scanning equipment in the North West where we have an abundance of globally renowned manufacturing businesses. This pioneering new scanning facility, which is portable and can be transported directly to client sites, will be a key resource for companies in unlocking the full potential of Industry 4.0.”

Dr Jim Morrison, Principal Investigator at the WiSAR Lab and Technology Gateway, highlighted how the new scanning facility will significantly bolster LYIT’s responsiveness in tackling industry challenges through applied R&D. “At the WiSAR lab, we have a renowned track record in industry engagement, providing real world solutions and direct access to new, emerging technologies and academic expertise for dozens of companies since our inception." Jim adds that, “with so many challenges facing the manufacturing industry, in the global business environment, such as Brexit, the Covid-19 pandemic and the ever-increasing pressure to accelerate automation, access to this world class scanning technology can be a game changer in improving supply chain efficiencies.”

WiSAR Technology Gateway Manager, Dr Stephen Seawright concluded by saying: “the manufacturing sector is a significant contributor to the local economy in the North West, with a high calibre of both indigenous and multinational businesses, and we are delighted to showcase this ground-breaking technology, which will enable businesses to validate their processes against international standards. This vital funding injection, which is one of several capital investments from Enterprise Ireland in recent years, will ensure that we remain responsive and proactive in meeting the evolving needs of our industry partners through our continued industry-centric research activities."