P2L2 Updates

The project is currently in its monitoring phase, which began on April 2018. Partners are currently implementing their respective regional action plans which would further develop regional innovation policies with respect to RIS3. This newsletter covers the various implementation activities of the project.

After 4 years of successful cooperation, on 18th November 2019, the Project organized its final conference in Bremen. Hosted by the University of Bremen and the Ministry of Economy Labour and Europe, the project event was honoured with the presence of several delegations from Nouvelle-Aquitaine, Piedmont, Podkarpackie, Denmark, Lithuania and Bremen composed of public administration, industry and research representatives.

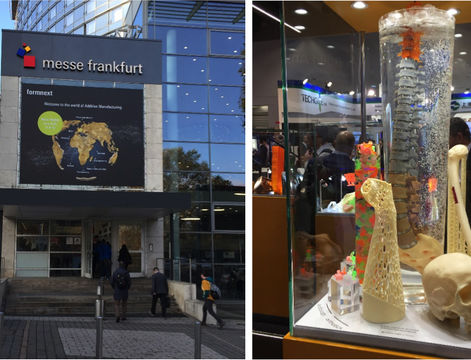

During the final conference, the participants had the opportunity of analysing the results of the implementation of the Regional Action Plans defined during the project. In addition, other regional good practices will be presented like, v.gr. the initiative the Bremen Initiative “Keys to Innovation” in cross-cutting sectors like new materials and additive manufacturing, or ECOMAT, a success story about effective regional science-industry cooperation.

P2L2 final conference in Bremen

The Bremen partners were happy to greet so many representatives from the P2L2 partner regions at the newly opened ECOMAT center on 18 November 2019 to the P2L2 final conference. Especially the high-level delegation from Piedmont region, lead by their regional Minister, Assessore Andrea Tronzano, underlined the strong potential the center offers for new forms of transnational cooperation.

Hans-Georg Tschupke, Head of the Department Innovation in the Bremen Ministry of Economic Affairs, Labour and Europe opened the conference by explaining the strong impact key enabling technologies have on the Bremen industrial sectors like aerospace, automotive and maritime technologies. Regional innovation policy focuses on technologies such as new materials, 3D printing and advanced layered manufacturing (ALM) and supports their development through knowledge hubs, networks and awards.

Hubertus Lohner of AIRBUS Operations acts as the head administrator of the ECOMAT center and presented the supporting structures the ECOMAT offers to its partners. Even within AIRBUS the center functions as a platform for cooperation between otherwise separate operations, i.e. material development, testing, production and quality insurance. These departments are jointly using laboratories and furthermore sharing them with external partners such as material research institutes and other companies. These joint activities make it necessary to set up an array of legal arrangements: What if an accident happens to an employee of one company while using the laboratory of another company. How to ensure that an aircraft part that is yet in development is not accidentally entering the production cycle. While this sums up to a lot of paper work, it is all the more worthwhile, because in the end the face-to-face contact leads to new developments. With AIRBUS aiming to reduce CO2 emissions in airborne traffic significantly within the next decades this is the way to go.

ECOMAT is cooperating closely with other northern German technology centers, the ZAL in Hamburg and the CFK North in Stade, Lower Saxony. ECOMAT partners are looking forward to returning the visit to Piedmont to follow up on opportunities for collaboration with the Manufacturing Technology Center and the Aerospace Center in Turin.

Facts and Figures:

- 75ME Invest by Bremen (building by Bremen invest; financed by a credit, no state aid)

- 18ME regional R&D funding (aerospace R&D-Programme: R&D-Infrastructure DLR, IWT; FIBRE)

- 22.000 m² office space and laboratory (occupancy rate over 90%, 80% in planning phase)

- 500 workplaces (70% Airbus; 30% Institutes, SME etc.)