Urban waste management is a most challenging issue for modern societies. Reducing pollution and saving environmental resources provides significant opportunities for local, national and international economic growth. For these reasons, one of the WINPOL stakeholders of the Municipality of Heraklion and the Region of Crete is leading the ANASA project. It aims at developing, integrating and commercializing an autonomous robotic system capable of categorizing and separating recyclable materials.

The development of an automated procedure for recyclable waste separation will significantly contribute in increasing the (currently low) recycling rates in Greece, for the benefit of the local societies and the economic enhancement of recycling activities across the country.

It has been a key issue for ANASA to design and implement a low-cost system that could be easily and quickly depreciable. The use of state-of-the-art robotic technology facilitates the synthesis of a high-productivity system that can decisively boost recycling activities at national and international level.

Overall, the “ANASA” Robotic Waste Separator (RWS) combines interesting features making it directly applicable for the recycling industry, with a significant potential for exploitation as a complete commercial product. These are:

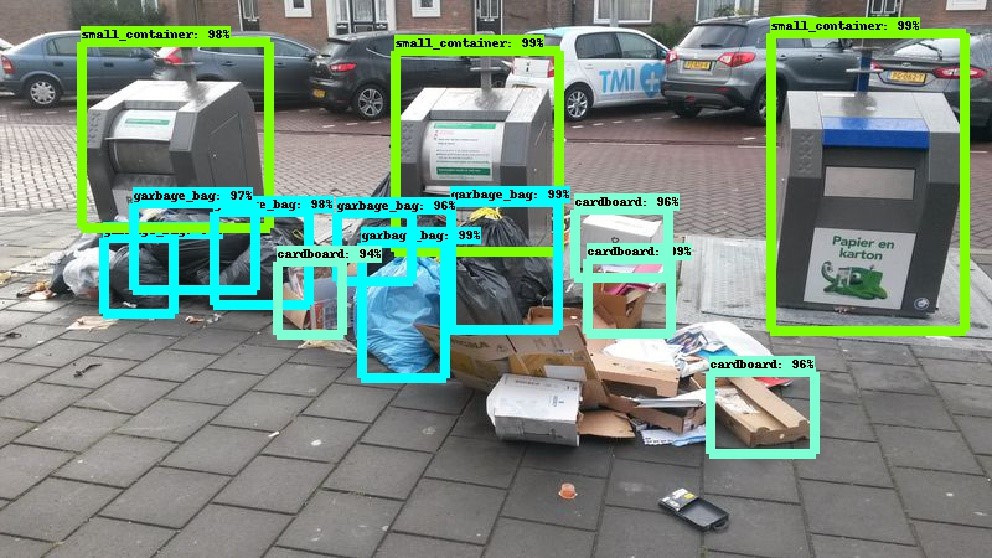

- high reliability in object recognition (material detection);

- low manufacturing costs;

- short sorting time per separated item (high speed);

- high accuracy and efficiency of the system;

- significantly low installation volume;

- ease of installation and operation to both old and new recycling industries.

The development of the RWS is based on the integration of mature technologies that are further improved by the academic partners of the consortium. In particular, the Technical University of Crete is undertaking the identification and spatial recognition of recyclable materials. This information is forwarded to the Foundation for Research and Technology Hellas that focuses on the targeted robot picking-and-placing of these materials to the appropriate classification bin. The guided integration of the aforementioned technologies takes advantage of TIERRA's extensive experience in industrial recycling processes.

By mid-2020, the RWS will be deployed in two different urban waste management industrial units, namely in DEDISA (processing recyclable wastes) and also in ESDAK (processing composite wastes), in order to test the reliability and validity of the system in real industrial environments. More specifically, RWS has different goals in each deployment site. In DEDISA it aims at catalytically enhancing the production capacity of the recycling plant that currently operates based on manual sorting, while in ESDAK it focuses on extracting recyclable objects from the composite wastes, which otherwise would end up in the local landfill.

The long-term operation of the entire system in hard industrial conditions will guide the focused adjustment of the RWS parameters to achieve optimal performance and excellent waste separation results. Furthermore, by highlighting and actively demonstrating the major benefits that the recycling industry may gain from the use of the implemented robotic recyclable waste sorter, the ANASA project paves the way for the commercial exploitation of the RWS as a complete and effective stand-alone system that has the potential to significantly boost the recycling market.

The dissemination of the project’s results through actions that focus on both the scientific community and the recycling industry, is expected to consolidate RWS as an important technological landmark of high-impact eco-innovation.